MR MULTI-PLY® Roof System | How It Works

The MR Multi-Ply® Roof System How It Works

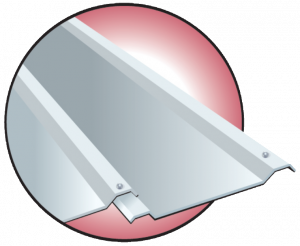

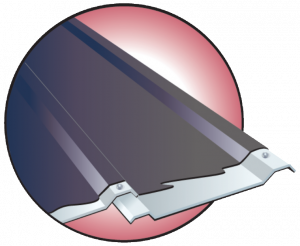

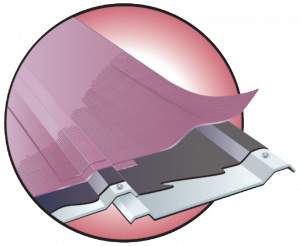

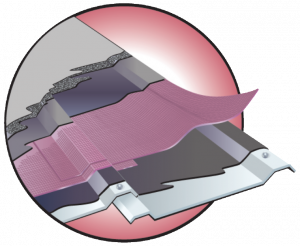

Base Metal Panel

The MR Multi-Ply system is ideal for pitched metal, transite, asbestos, and fiberglass roofs.

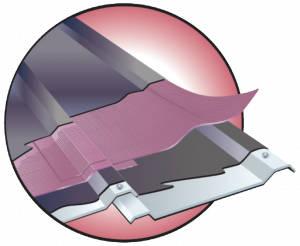

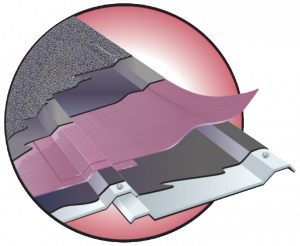

2nd Asphalt Coating

A second layer of asphalt seals in the membrane and provides further protection.

1st Asphalt Coating

A layer of liquid asphalt is laid down directly on the roof to form the base of the system.

Granule Finish

The final layer, the energy-efficient granules, ensures your roof stays cool.

Polyester Membrane

The polyester membrane ensures no leaks are generated by the roof and adds 100K lbs. of tensile.

Optional Aluminum Reflective Finish

Available in a variety of colors.

"Thank you for the roofing scope of work photos! – I’d like to also commend Josh for his ability to Adapt and Overcome a strict timeline and keep his crew/Team Safe during this project. There were a few curve balls thrown "Bad weather and logistically maneuvering around our production needs."

"Thank you for the roofing scope of work photos! – I’d like to also commend Josh for his ability to Adapt and Overcome a strict timeline and keep his crew/Team Safe during this project. There were a few curve balls thrown "Bad weather and logistically maneuvering around our production needs."