Formerly

Wise Alloys (Now Constellium), chose us to cover 80,000 Sq. Ft. of transite roof system at their Muscle Shoals facility. The cost to remove the transite panels would have been three times that of our MR Multi-Ply® Roof System. Removing the transite system would have also caused production to shut down due to the age and nature of the material.

It was determined that dust from a removal would throughout the work site and risk releasing asbestos fibers into the air. OSHA and the EPA would have to be present on-site, directing the project. This would also call for tons of unnecessary paperwork, not to mention having to monitor the workers on-site for many years after abatement.

-

- Transite is extremely hazardous if disturbed.

-

- At this age, the panels are degrading and brittle. Our crew must stand on specially engineered platforms for proper weight distribution.

-

- Areas with high degradation must be covered and completely sealed.

-

- Any past penetrations from bolts, screws, fasteners, etc. must also be re-covered and sealed.

Northwestern Alabama receives an average of 52.16” of rain

and 117 days of precipitation. Any roof system

will begin to fail in this environment.

Transite begins to fail after about 50-70 years, depending

on surrounding conditions. This particular facility had gone

so long without repair, leaks had begun in multiple areas.

Laminating the MR Multi-Ply® Roof System directly to the

Transite panels added 80-100 thousand lbs per Sq. Ft.

of tensile strength to the structure.

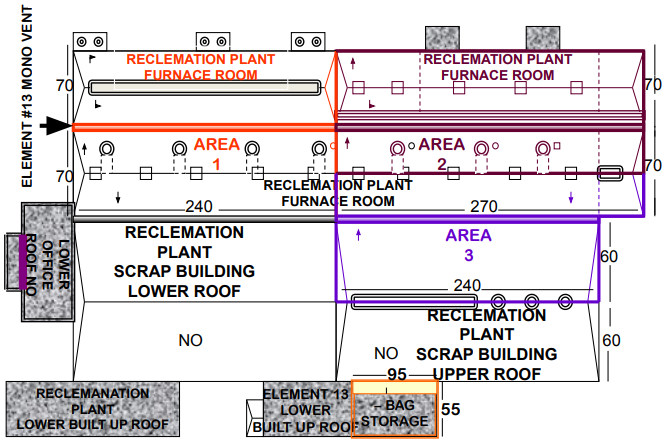

North wall of the facility

North wall in progress

This solution allowed maintenance personnel to:

-

- Safely access the roof again

-

- Stop any further deterioration to the panels

-

- Successfully seal the roof to be water tight

-

- Keep production running throughout the entire process

Application of MR Multi-Ply® Roof System. Brooming down a second layer of asphalt over the membrane.

Constellium in progress